Manufacturers select copper for commercial refrigeration because it delivers superior Heat Transfer, corrosion resistance, and long-term reliability. A Copper Fin Heat Exchanger handles temperature changes easily, resists leaks, and reduces maintenance. These features improve energy efficiency and extend equipment lifespan, making copper the preferred choice in demanding environments.

Key Takeaways

- Copper fin heat exchangersdeliver fast and Efficient Cooling due to copper's superior thermal conductivity, which lowers energy costs and improves performance.

- Copper resists corrosion and lasts longer than aluminum or steel, reducing maintenance needs and preventing leaks in commercial refrigeration systems.

- Using copper fins helps businesses save money over time by cutting energy use, minimizing repairs, and supporting compact, reliable refrigeration designs.

Copper Fin Heat Exchanger: Superior Efficiency and Performance

Unmatched Thermal Conductivity

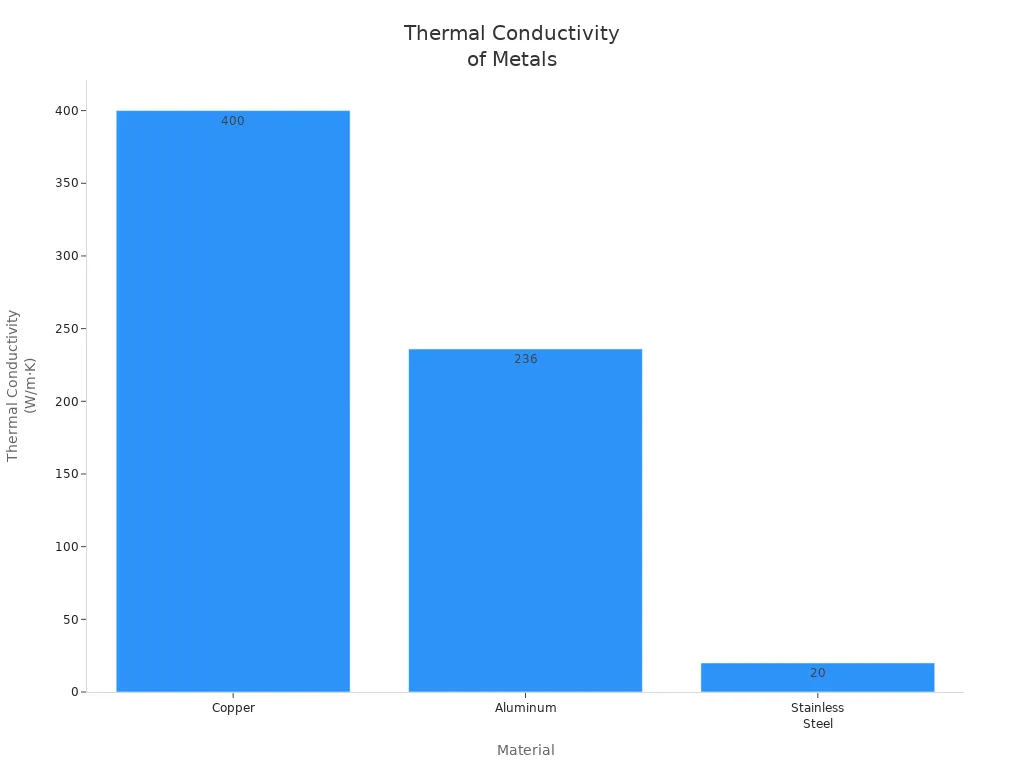

Copper stands out as the top choice for heat exchangers because of its exceptional thermal conductivity. Manufacturers rely on copper to transfer heat quickly and efficiently. The thermal conductivity of copper reaches up to 401 W/m·K, which is about 20 times higher than stainless steel and nearly twice that of aluminum. This property allows copper fin heat exchangers to move heat away from refrigerated spaces faster, keeping food and products at safe temperatures.

| Material | Thermal Conductivity (W/m·K) | Relative Comparison |

|---|---|---|

| Copper | ~400-401 | Baseline |

| Aluminum | ~235-237 | ~60% lower than copper |

| Stainless Steel | < 20 | ~20 times lower than copper |

Copper fin heat exchangers use this advantage to deliver rapid cooling and stable temperatures. Scientific studies show that copper fins can improve heat transfer efficiency by about 20% compared to aluminum fins. This improvement means lower energy costs and better performance for commercial refrigeration systems.

Impact on Commercial Refrigeration Systems

Copper fin heat exchangers play a key role in reducing energy consumption and operating costs. Their high thermal conductivity and increased surface area allow systems to cool faster and use less electricity. Operators benefit from lower utility bills and more reliable equipment.

- Copper fin heat exchangers improve heat transfer efficiency, leading to reduced energy consumption.

- Copper’s durability ensures longer service life and less frequent maintenance.

- Compact designs save space and optimize energy use.

- These features help businesses lower operational costs and maintain efficient refrigeration.

Smaller diameter copper tubes also reduce the amount of refrigerant needed, which lowers material costs and supports safer system designs. Manufacturers can create more compact units without sacrificing cooling power. These benefits make copper fin heat exchangers the preferred solution for modern commercial refrigeration.

Real-World Example: Restaurant Walk-In Coolers

Restaurant owners depend on walk-in coolers to keep ingredients fresh and safe. Copper fin heat exchangers help these systems maintain consistent temperatures, even during busy hours. The rapid heat transfer keeps food at the right temperature, reducing spoilage and waste.

A scientific study found that copper-coated heat exchangers increased heat transfer by 1.59 times compared to plain plate units. This improvement resulted in better cooling performance and lower energy use. Restaurants using copper fin heat exchangers experience fewer breakdowns and spend less on repairs. The compact design also allows for more storage space inside the cooler.

Copper fin heat exchangers are not limited to walk-in coolers. They are also used in beverage display coolers, bottle coolers, and split-type heat pump systems. These applications show the versatility and reliability of copper in commercial refrigeration.

senjun: Leading Manufacturer of Copper Fin Heat Exchangers

Ningbo Senjun New Materials Co., Ltd. leads the copper fin heat exchanger industry in China, holding a 35% market share. Senjun specializes in the research, development, and production of wire tube condensers and copper aluminum fin heat exchangers for refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers.

Senjun drives innovation in copper fin heat exchanger technology. The company uses advanced corrosion-resistant alloys to increase durability. Modular and compact designs make installation and scaling easier. Senjun integrates digital tools for product testing and improvement, focusing on energy efficiency and customization for refrigeration and HVAC applications.

Senjun applies rapid prototyping, AI-driven optimization, and 3D printing to accelerate development and enhance thermal performance. The company has developed smart heat exchangers with IIoT integration and real-time monitoring, enabling predictive maintenance and energy optimization.

Senjun’s commitment to quality and innovation ensures that commercial refrigeration systems operate efficiently, reliably, and cost-effectively.

Durability, Maintenance, and Comparison to AlternativesCorrosion Resistance and Longevity

Copper fin heat exchangers stand out for their impressive resistance to corrosion. Copper forms a stable oxide layer on its surface, which acts as a natural shield against environmental damage. This protective barrier is especially important in commercial refrigeration, where systems face exposure to moisture, chemicals, and varying temperatures. Copper resists dezincification, a type of corrosion that can cause leaks in other metals. In humid or coastal environments, copper remains the preferred choice because it does not pit or degrade as quickly as aluminum. Steel, while strong, does not match copper’s corrosion resistance in typical refrigeration settings.

- Copper’s oxide layer protects against corrosion, even in salty or humid air.

- Aluminum is more likely to corrode and clog, especially in water drain applications.

- Copper’s durability and corrosion resistance make it ideal for long-term use in refrigeration.

Copper fin heat exchangers maintain their performance over many years, reducing the risk of leaks and system failures. This longevity translates to fewer replacements and lower maintenance costs for commercial operators.

Ease of Installation and Repair

Installation and maintenance play a critical role in the overall cost and reliability of refrigeration systems. Copper fin heat exchangers require careful handling due to their weight, but their manufacturing process allows for slightly looser plumbing tolerances. This flexibility can simplify installation in complex commercial setups. Copper’s strength supports secure welding, which creates durable connections and reduces the risk of leaks.

| Aspect | Copper Fin Heat Exchangers | Aluminum Heat Exchangers | Steel Heat Exchangers |

|---|---|---|---|

| Manufacturing Cost | Lower | Lower | Highest |

| Installation Handling | Heavier | Lighter | Heavier |

| Plumbing Tolerances | Looser | Tighter | Tighter |

| Attachment Methods | Welding, Rivets, Screws | Welding, Rivets, Screws | Welding |

| Installation Time | Moderate | Shorter | Longest |

Routine maintenance for copper fin heat exchangers is straightforward. Technicians inspect the tubes and fins quarterly, clean dust and debris with soft brushes or compressed air, and check for leaks. Annual professional servicing ensures optimal performance. Copper’s durability means fewer repairs and less downtime, which is essential for businesses that rely on continuous refrigeration.

Regular inspections and simple cleaning routines help copper fin heat exchangers deliver reliable performance year after year.

Aluminum and Steel: Why They Fall Short

Aluminum and steel heat exchangers offer some advantages, such as lighter weight or lower upfront cost, but they present significant drawbacks in commercial refrigeration. Aluminum, while easy to handle and install, is more prone to corrosion, especially in environments with water or chlorine. This leads to faster degradation and more frequent maintenance. Steel, particularly stainless steel, provides excellent strength and corrosion resistance but comes with higher manufacturing and installation costs. Its lower thermal conductivity also means less efficient heat transfer, resulting in higher energy consumption.

| Material | Main Drawbacks |

|---|---|

| Aluminum | Lower strength, prone to corrosion, frequent maintenance, faster degradation in harsh settings |

| Stainless Steel | Heavier, higher cost, complex fabrication, lower thermal conductivity, increased energy use |

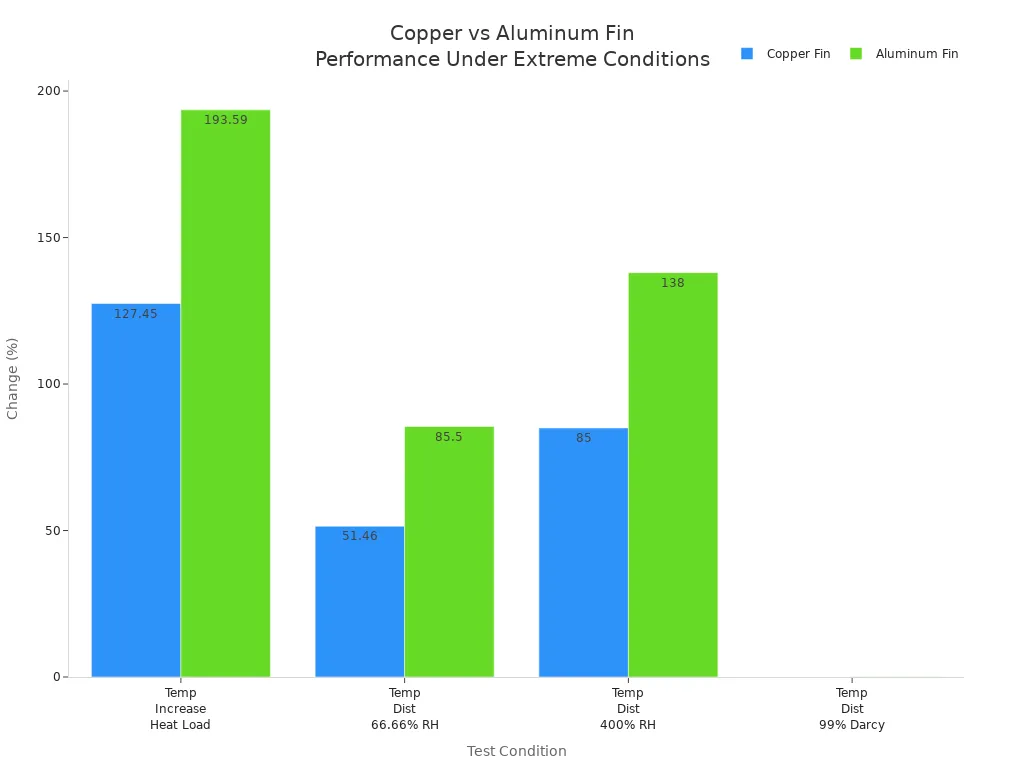

Recent advancements in aluminum technology have improved efficiency and reduced weight, but copper still outperforms aluminum in extreme temperature and humidity conditions. Copper fin heat exchangers maintain better temperature distribution and condensation, making them more suitable for demanding commercial applications.

Industry Standard and Long-Term Cost Savings

Copper fin heat exchangers have become the industry standard for commercial refrigeration due to their balance of efficiency, durability, and ease of maintenance. Their high thermal conductivity leads to lower energy consumption, which reduces operating costs over time. The robust construction and corrosion resistance of copper minimize the need for frequent replacements, supporting long-term savings.

- Copper fin heat exchangers enable the use of natural refrigerants with low global warming potential, supporting sustainability goals.

- Their compact design reduces refrigerant charge, lowering environmental impact and operating expenses.

- Leading manufacturers, such as senjun, offer advanced copper fin heat exchangers that meet strict industry standards and provide reliable warranties.

Many manufacturers back their copper fin heat exchangers with warranties ranging from 10 years to lifetime coverage, reflecting confidence in their longevity and performance. Regulatory standards ensure that these products meet safety and efficiency requirements, further solidifying their place as the preferred solution in commercial refrigeration.

Copper Fin Heat Exchanger technology stands out in commercial refrigeration.

- Copper provides high thermal conductivity, ensuring efficient cooling.

- Its corrosion resistance and antimicrobial properties support durability and hygiene.

- Maintenance remains simple, with copper’s strength and malleability allowing reliable, long-lasting performance.Manufacturers like senjun set the industry standard.

FAQWhat makes copper fin heat exchangers ideal for commercial refrigeration?

Copper offers high thermal conductivity and strong corrosion resistance. These features help refrigeration systems cool quickly and last longer.

How does senjun ensure the quality of its copper fin heat exchangers?

Senjun uses advanced manufacturing and strict quality control. The company tests every product to meet industry standards and customer needs.

Can copper fin heat exchangers help reduce energy costs?

Yes. Copper fin heat exchangers transfer heat efficiently. This efficiency lowers energy use and helps businesses save money on electricity bills.

Media Contact

Company Name: Ningbo Senjun New Materials Co., Ltd.

Email: Send Email

Phone: +86-574-83073262

Address:3rd Floor, Building 1, 68 Chunchao Road, Yinzhou District

City: Ningbo

State: Zhejiang

Country: China

Website: https://www.senjuncooler.com/