McCormick Industries, an Appleton, WI-based precision CNC manufacturer, today announces additional available capacity for its aerospace machining capabilities, reflecting its continued commitment to supporting customers who require high-tolerance components for demanding flight and propulsion applications. As the company increases the throughput of its precision turning, Swiss machining and multi-axis milling operations, McCormick Industries is positioning itself to serve a growing number of aerospace programs while maintaining the consistent accuracy for which it is known. This development reinforces the value the company places on delivering dependable aerospace engineering from McCormick.

The organization’s expanded machining availability comes as aerospace suppliers seek reliable partners capable of holding tight geometries, ensuring repeatable tolerances, and working across a wide range of materials used in aircraft and space systems. McCormick Industries continues to invest in tooling, programming, and workflow efficiencies that allow its team to manage complex parts with dimensional precision measured in ten-thousandths of an inch. These capabilities are essential in aerospace work, where even minor deviations can affect safety, performance and long-term durability.

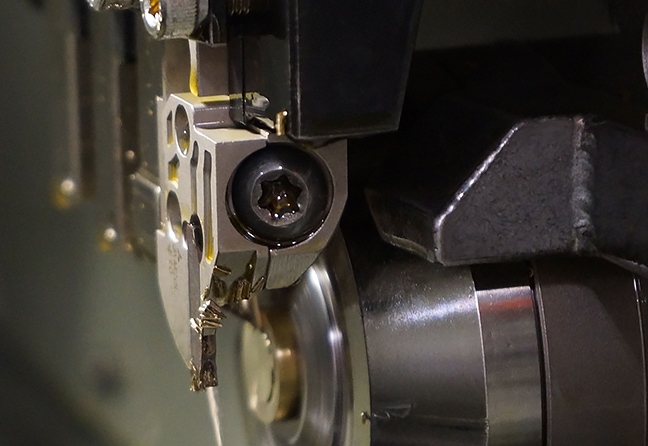

McCormick’s operations include CNC turning, high-precision Swiss turning for small-diameter components, and advanced CNC milling performed on vertical machining centers designed for intricate contours and tight positional accuracy. The company’s ability to accommodate both small and moderately sized components enables it to serve programs that rely on fine, detailed parts as well as more structurally significant elements. By strengthening the capacity of these processes, McCormick Industries offers customers improved scheduling flexibility without compromising the quality controls integral to aerospace work.

According to CEO Gary Hermsen, “Increasing our machining capacity allows us to support clients who depend on reliability at every stage of production. Our team remains focused on delivering aerospace CNC machining from McCormick with the precision and consistency required for mission-critical components.” His statement underscores the company’s philosophy that machining excellence is as much about process discipline as it is about equipment sophistication.

McCormick Industries maintains ISO 9001:2015 certification, reinforcing its structured approach to quality management and continual improvement. The company’s inspection protocols include the use of calibrated measurement systems and documented verification procedures, ensuring that every component meets the specifications established by aerospace manufacturers. This emphasis on traceability and documentation helps customers satisfy industry compliance and audit requirements.

The organization routinely works with materials essential to aerospace manufacturing, such as titanium, stainless steel, high-strength alloys, aluminum and specialty metals selected for thermal stability or favorable strength-to-weight ratios. McCormick’s machining strategies are tailored to each material’s characteristics, enabling the company to achieve consistent results even when working with metals known for machining difficulty. This adaptability allows aerospace clients to source parts that must endure extreme conditions ranging from pressure fluctuations to thermal cycling.

As new aerospace projects emerge across commercial aviation, defense systems and space-vehicle development, McCormick Industries’ added capacity provides a path for customers who are expanding production volumes or initiating new component designs. Whether supporting prototype iterations or full production runs, the company’s approach centers on communication, manufacturability feedback and collaborative problem-solving with engineering teams.

McCormick’s capabilities also extend to coordinating value-added finishing services, giving aerospace clients a streamlined path from raw material to a completed, installation-ready part. By managing these details with trusted partners, the company reduces the logistical complexity that often comes with aerospace manufacturing.

The increased machining availability supports a wider strategic goal for McCormick Industries: to offer dependable, precision-driven solutions that evolve alongside the needs of the aerospace sector. As programs advance and design requirements become more specialized, the company’s investment in process capacity ensures that it can meet heightened expectations without extending lead times.

With a focus on precision, accountability and long-term client support, McCormick Industries continues to build on its reputation as a machining partner capable of meeting aerospace standards. The added capacity reinforces the organization’s ability to support both established and emerging programs with consistent quality and reliable delivery schedules.

###

For more information about McCormick Industries, contact the company here:

McCormick Industries

Gary Hermsen

920-954-9648

info@mccormickind.com

1103 South Perkins Street

Appleton, WI 54914